Positive Displacement Pumps

Volumetric pumps are nowadays considered as useful power providers for several applications, due to their features regarding the wide operating condition range, small dimensions, high reliability and power over weight ratios. They are commonly adopted as oil supplying components in various automotive subsystems, where the design of such machines finds one of its most advanced expressions.

Volumetric pumps are nowadays considered as useful power providers for several applications, due to their features regarding the wide operating condition range, small dimensions, high reliability and power over weight ratios. They are commonly adopted as oil supplying components in various automotive subsystems, where the design of such machines finds one of its most advanced expressions.

In this field of application, the peculiarity of such machines is given by the compelling need to accomplish the necessary working characteristics together with other essential constraints related to weight and global size minimization, mechanical efficiency maximization and NVH behavior improvement.

Our main goal is to define analytical and experimental methods, as well as numerical tools, to improve the efficiency of the design process, from the initial geometry determination to the performance prediction. The research team is also experienced in a wide variety of experimental tests, from performance mapping to NVH characterization and cavitation detection.

External Gear Pumps

Research is mainly focused on modeling the gear pair dynamics, the machine fluid-dynamic behavior and their interaction by means of fully-coupled numerical models. In this context, the modeling strategy of advanced design solutions such as helical gears, multiple coaxial stages and not-unitary transmission ratio constitutes a central topic.

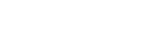

Balanced/Variable displacement Vane Pumps

Cam ring design and tribo-dynamic analysis of the vane-cam ring mechanism represent the current core of the research activity, which takes advantage of years of experience on modeling the fluid-dynamic performance of such machines.

Dynamics of Rotating Machines

The dynamic modeling of complex mechanical systems has been characterized by a deep interest in academic and industrial research departments since the diffusion of the first computers. Nowadays, the possibility to solve large problems with an acceptable computational time, including the presence of multiple nonlinearities, stiff behaviors and multi-physic interactions, is giving a further incentive to this research field.

The dynamic modeling of complex mechanical systems has been characterized by a deep interest in academic and industrial research departments since the diffusion of the first computers. Nowadays, the possibility to solve large problems with an acceptable computational time, including the presence of multiple nonlinearities, stiff behaviors and multi-physic interactions, is giving a further incentive to this research field.

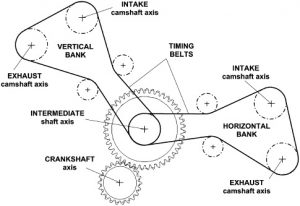

During the last decade, the research team has experienced various modeling approaches, from the analytical and lumped-parameter one, to the application of flexible multibody strategies, Finite Element Methods as well as the Craig-Bampton Method. Studies have been based on commercial codes as well as proprietary software.

The research activity has faced the definition of dedicated models for peculiar machines, such as linear and bowl vibratory feeders, chainsaws and brush cutters, but the main focus has always been centered on geartrains, driveline and crackline structures. Within this framework, automotive subsystems currently represent the main topic of research for the MechVib team involved in dynamic modeling, which is working on the implementation of proprietary software.

Research Activities